The incinerator will certainly have chimney, castable premium refractory cellular lining in addition to heater shell, perforated blind for the major along with additional burning chambers and also air blood circulation system.

The heater shall also have the following:-.

– – Ash door. – Main as well as additional heating units as well as additionally fans.

– – Temperature degree indication gadgets.

– – Electric wiring from the neighborhood isolator.

– – FD follower.

– – Air receiver. – Air ductwork total with air dampers.

– – Pressure along with temperature level evaluates.

– – Totally wired control board

The bulk oil storage tank will have an ability of 10,200 litres as well as be placed at 0.5 m over ground on a firm concrete cradle, total amount with the following:-.

– – Drainpipe pipeline

–.

– – Air vent pipe

–. – Oil degree indication. – Access to ladder to the top of the

– storage tank. – Finishing of the container with a minimum of 2No. layers of bituminous paint.

– – Manhole cover total amount with a gasket.

– – Dip stick. – Any kind of various other vital gadget.

E-2

The daily oil container of capacity 1,800 litres as well as measurement 1220x1220x1220mm pushed steel storage tank high shall be positioned 2.5 metres high over ended up floor degree on a steel stand, highly secured on the ground and additionally the steel participants to be bolted. The day-to-day oil container shall have an oil level indication, ease of access manhole, washout, overflow, inlet along with outlets links as well as portal shutoffs.

The adjacent pipe of 50mm dimension between both tank will certainly be class ‘‘ C ‘black mild steel pipeline, total with a 50mm diameter filter. The burner fuel supply pipeline from the daily container will certainly be a 25mm size class ‘‘ C ‘black mild steel.

The adhering to will in addition be supplied.

– – 25mm size fire shutoff.

– – 25mm dimension high capability strainer.

– – home heating tap along the heating system supply pipe, 25mm size

The heating unit supply pipe will have 25mm thick fiber glass insulation as well as perform with scale 20SWG galvanized steel sheet.

The tenderer will give all the required controls for proper safety and likewise acceptable working of the installment.

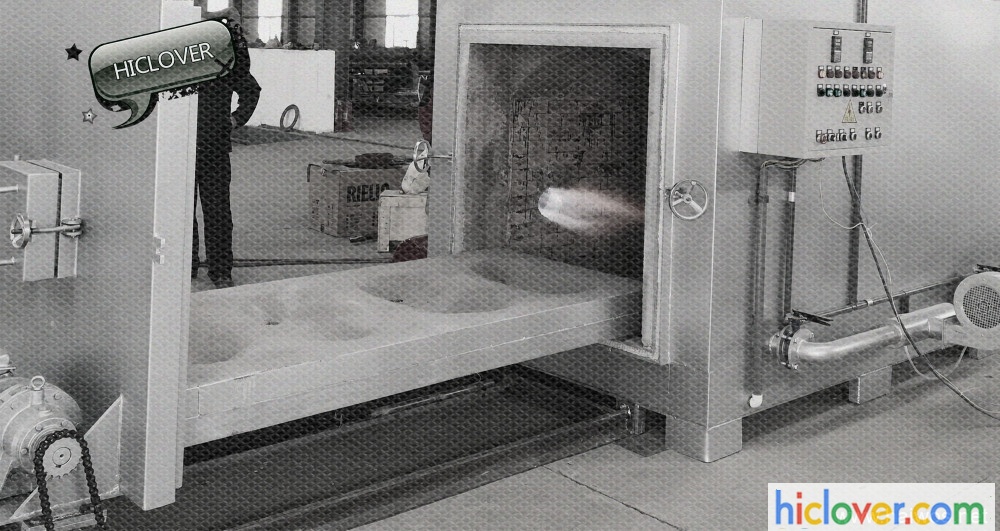

1.1.1 HEATING UNIT

The heater will appropriate for 35 sec redwood No. 1 range fuel oil. It will certainly be durable in building and building and also be generated in stars iron or other ideal products complete with positioning plates. It requires to be likewise demountable and quickly mountable for comfort of cleansing and upkeep. The heating unit will have a proper supply of oil which will quickly stir up along with melt in a protected way. Sufficient arrangement will certainly be supplied to prevent any type of solid issue in the oil, or any kind of type of concern that may separate out from the oil from damaging any parts or chocking of any type of sort of orifices or shutoffs. The free filtering system area should certainly be sufficient to see to it that the filter does not need taking apart for cleaning up regularly than every year. The burner will have fire guidance by photo-electric cell with simultaneous series controller for automated start up, running as well as shut-down of the burner.

The burner will have all the important controls e.g.Solenoid shutoffs, ignition controls, photo electrical cell gas safety and security and protection controls, low stress fuel supply cut-off and so on.

The heating unit will certainly please BS 799: part 3 along with 6 1981 or any various other pertinent British standard.The burner will be as NU-WAY versions or equal and likewise approved.

1.1.2 REGULATES

The incinerator shall run in an automatic fashion with all the called for controls. These controls are to include protection components such as fire failing device, pilot lights, integrates, beginners, overload contactors, ON in addition to OFF switches for heating systems and also fans, burning chamber temperature level indicators for additionally 2nd as well as key chambers and so on.

i) Electric ignition switch ‘‘ ON’ prior to the oil is supplied.

ii) Delayed go back to re-start readying to allow purging.

iii) Re-start after short-lived electrical supply failing.

iv) Favorable safety and security and security lock-out in instance of flame stopping working from whatever reason.

v) Red signal light on control panel to indicate safety and security locked out.

vi) Photo electric safety cell as fire stopping working tool.

The controls will be placed on suitable control panel to be placed in a position easy to assess as well as take care of from the charging door side of the burner.

The control board will certainly be created from anodized, 16SWG, light steel sheet.