Doubel Combustion Chamber

All Incinerators are Doubel Combustion Chamber with One Fuel Burner Each. After Burner Technology for Completely Combustion and Cleaner World.

Read MoreHigh Temperature Incineration

Temperature Range 800 Degree to 1200 Degree in Combustion Chamber. Temperature Thermocouple Monitor and Controller. High Quality Fire Brick and Refactory Cement.

Read MoreGet Lastest News

There are latest incinerator news like technical, public news, business tender for medical waste incinerator,animal incineration, pet cremation

Read MoreNanjing Clover Medical Technology Co.,Ltd.

Email: sales@clover-incinerator.com | Tel: +86-25-8461 0201

Regular model incinerator for market with burning rate from 10kgs to 500kgs per hour and we always proposal customer send us their require details, like waste material, local site fuel and power supply, incinerator operation time, etc, so we can proposal right model or custom made with different structure or dimensions.

Incinerator Model YD-100 is a middle scale incineration machine for many different usage: for a middle hospital sickbed below 500 units, for all small or big size family pets (like Alaskan Malamute Dog), for community Municipal Solid Waste Incineration, etc. The primary combustion chamber volume is 1200Liters (1.2m3) and use diesel oil or natural gas fuel burner original from Italy.

Latest Post

INCINERATOR SPECIFICATION Capacity UPTO 20 kg/hr

Material: STAINLESS STEEL STACK, REFRACTORY CONCRETE LINING SPECIAL INSULATION MATERIAL

With burner: 15 C 20 KW

Temperature: PRIMARY CHAMBER = 800°C AND SECONDARY CHAMBER = 850 – 1200° C

Sufficient heat generation for secure and complete combustion 600-800 °C in the first chamber and >1000 °C in the second chamber

Easy transportation on standard EURO-pallets

Constructed in a modular fashion easy on-site movement and assembly with a minimum of equipment and technical skills;

For the destruction of problematic waste like sharps, amputates and body parts, wet or moist matter;

Off-gas quality: moderate smoke emissions during one quarter of the total incineration time; no visible emission during three quarters. AS PER INTERNATIONAL STANDARDS

The remaining ash approximately 5-10% in weight and below 1% in volume of the original waste AS PER INTERNATIONAL STANDARDS

Chimney height at least 5 m above the incinerator 5m ABOVE FROM THE GROUND

Temperature resistance of the lining at least 1,200 °C

incinerator type of pyrolytic medical waste incinerator capacity

Including:Incinerator: Structure to be specified

The mark to be specified

Water temperature: 800 to 1000 ° C;

Refractory

Temperature of more than 1100 ° C + obtained;

Capacity: 20-50 kg / hour

Fireplace: 4 to 6 meters high;

Dimension 70 cmx70 crn

Height: 1.10 meters

Fuel: coal;

Aspiration: natural

– A receiving cage for biomedical waste;

– A combustion chamber with a chimney with a filter to retain the ashes;

Chimney section: about 300 cm; With a minimum height of 6 m

Door size: approximately 50×60 cm

Supplied with a 500 liters fuel tank and all necessary accessories for installation.

– INCINERATOR for pharmaceutical waste treatment with a scrubbing system

With the following technical data:

1. One pharma solid waste incinerator unit containing two combustion chambers and based on steel base with scrubbing

system.

2. Working hour /day: minimum 10 hours/day.

3. Capacity: Approximated 150 kg/hr. Over 10 hrs.

4. Wastes characteristics:

· BULK density: 70 – 100 kg/ bm³.

· Calorific value: 2000-3000 kcal / hr.

· Moisture content: 20-30%by weight.

· Ash content: 2 – 8 % by weight.

· Plastic content: 15-20 % by weight.

5. Two combustion chambers.

6. Operating temperatures:

· First chamber: not less than 700 – 800 °c.

· Second chamber: not less than 1200 °c (during steady operation).

7. The burners should be automatically switched off if any of the combustion chambers doors is open.

8. The burners of the first and second combustion chambers are selected for burning diesel oil (light fuel).

9. Automatic loader and unloader to be provided.

10. Exhaust gases to be comply with International Environmental code and requirements.

hospital incinerator manufacturer

Up to 600kgs per ten-hour day of Type IV pathological waste or red bag waste rated at 2200 BTU’s per kg, based on batch

loading twice daily.

Incinerator, 20 kg/hr Burn Capacity (min. 1200 kgs. Waste Feed Capacity per day) (4-6 hours operations) (Power Supply

380V, 50Hz, 3Ph)

Capacity: 30 kg/hr.

Number item: 01 unit

Could you please send us cataloge detail for Pet Cremation of dogs, cats.

– Please services require: General about Cremation system which is suitable

for your products, technical transfer and training for operators.

Containerized Incinerators Operational Capabilities • PROCESS 1+ TONS / DAY • OPERATED WITH LIMITED TRAINING • REGULAR

MAINTENANCE CAN BE COMPLETED WITH LIMITED TRAINING • COMPLIES WITH EURO / OR US-EPA EMISSION STANDARDS • ABILITY TO BURN

WASTE LUBRICANTS (POL) • HANDLE ORGANIC SOLIDS (TO INCLUDE RMW) • DEPLOYABLE • MOBILE • 24 HRS OF CONTINUOUS USE •

AUTOMATIC LOADING SYSTEM • AUTOMATED ASH REMOVAL SYSTEM • GAS SCRUBBING SYSTEM • 95% REDUCTION OF SOLID WASTE • OPERATE

OFF DIESEL OR FUEL OIL • CAPABLE OF BURNING 4 UNITS OF WASTE PER UNIT OF FUEL • ABLE TO TAKE ALL COMBUSTIBLE WASTE TO

INCLUDE: PAPER, PLASTIC, CARDBOARD, FOOD, USED OILS, SLUDGE, OILY RAGS, WOOD PALLETS. • NO PRE-TREATMENT OF WASTE

REQUIRED • VENDOR REPAIR OFFERED AT POINT OF SHIPMENT • FIVE (5) YEAR COMPONENT WARRANTY FROM DATE OF ACCEPTANCE

Technical Specifications • OPERATION MANUAL AND TRAINING MANUAL FOR EACH INCINERATOR • SET UP AND INSTALLATION

INSTRUCTION MANUALS • BLUE PRINT/ SCHEMATIC PROVIDED THAT OUTLINES THE PHY SICAL DIMENSIONS OF THE 20’ INCINERATORS •

INCINERATORS COMPOSED WITH HEAVY DUTY WELDED CONSTRUCTION • OPERATED AND TRANSPORTED IN 20’ INCINERATORS (CONTAINERS) •

FULL FRONT AND OPTIONAL REAR ACCESS • PRIMARY / SECONDARY TEMPERATURE CONTROLS • COMBUSTION AIR DAMPER • VAPOR TIGHT

LIGHT FIXTURES & 120V OUTLET • OUTDOOR PLU-IN RECEPTABLE FOR ELECTRICAL SOURCE • OUTDOOR FUEL TRAIN WITH SHUT-OFF • LOAD

RAMP • SKID – MOUNTED FUEL TANK • ELECTRICAL AND FUEL OIL CONNECTORS • CONTROL PANEL AND AIR LOUVER • AIR MANIFOLD

ACCESS AND UTILITY BULKHEAD • GALVANIZED SHIPPING COVERS • FUEL, WATER AND OIL CONNECTOR LINES • PRIMARY AND SECONDARY

BURNERS • FULLY INTEGRATED PLC CONTROL SYSTEM • FACTORY TESTED, WIRED PRIOR TO SHIPMENT • MOBILITY: NO HEAVY LIFT

EQUIPMENT NEEDED FOR SET UP OR TEAR DOWN • HEIGHT RESTRICTED TO THE HIGHEST POINT ON BASE OR UNDER 15FT TALL

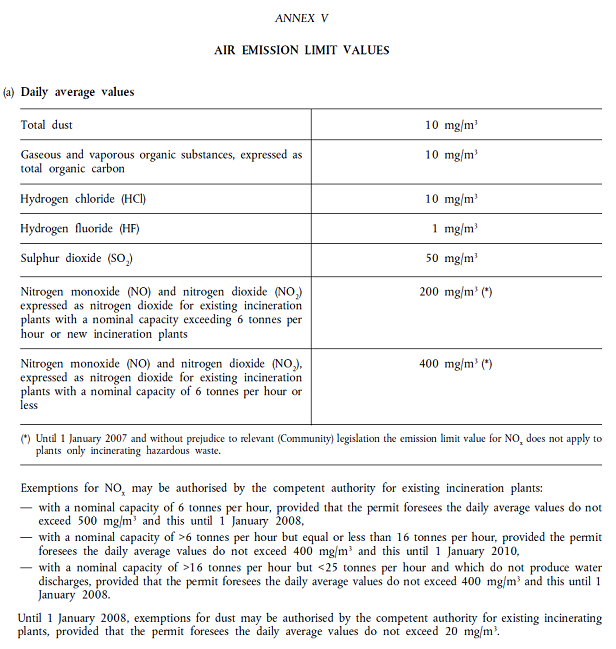

emissions Directive 2000/76/EC