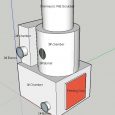

Doubel Combustion Chamber

All Incinerators are Doubel Combustion Chamber with One Fuel Burner Each. After Burner Technology for Completely Combustion and Cleaner World.

Read MoreHigh Temperature Incineration

Temperature Range 800 Degree to 1200 Degree in Combustion Chamber. Temperature Thermocouple Monitor and Controller. High Quality Fire Brick and Refactory Cement.

Read MoreGet Lastest News

There are latest incinerator news like technical, public news, business tender for medical waste incinerator,animal incineration, pet cremation

Read MoreNanjing Clover Medical Technology Co.,Ltd.

Email: sales@clover-incinerator.com | Tel: +86-25-8461 0201

Regular model incinerator for market with burning rate from 10kgs to 500kgs per hour and we always proposal customer send us their require details, like waste material, local site fuel and power supply, incinerator operation time, etc, so we can proposal right model or custom made with different structure or dimensions.

Incinerator Model YD-100 is a middle scale incineration machine for many different usage: for a middle hospital sickbed below 500 units, for all small or big size family pets (like Alaskan Malamute Dog), for community Municipal Solid Waste Incineration, etc. The primary combustion chamber volume is 1200Liters (1.2m3) and use diesel oil or natural gas fuel burner original from Italy.

Latest Post

Waste incinerator consumer guider”

Oil Fired Incinerator

Basic Info.

Additional Info.

Product Description

Q: What’s kind of waste may use within this gear? A: This gear for pet creature, medical waste, Municipal waste, reside waste. Prohibit any volatile and radiation substance, liquid waste and gas waste.

Q: Incinerator Smoke Standard A: China Government Standard: No. GB18484-2001.

Q: Remedy capacity A: Clover incinerator use time daily to 24 hours. Between every feed/combustion time, there are about 0.5-1 hours cooling time and time for feeding squander. Actual combustion time per day is around 16 hours. The life of incinerator between 5-10 year according to use.

Ordinarily, we proposition customer buy crematory according to animal size. For small creature, cats, birds suit for small scale crematory (Model YD-15C/20C/30C). For additional large animals, suit for model A1200, A1500, A2400, A4000.

Q: Assembly and Testing A: We supply all documents and incinerators easy to setup and functionality. Client can send people visit our factory to learn operation and installation. Normally, waste scale cost, waste to power sprinklers, incinerator capacity of 40 kg/hr, wat is the ability of burner to the incinerator of 100kg/hr, water dusti filters, We do not send engineer to local site if not ask. The dispatch cost is extra according to order.

Q: Combustion Temperature A: The first combustion chamber: 800-1000 centi level. The second combustion chamber: 1000-1200 centi level. PLC mode according to model and order.

Q: Operation and maintenance costs A: Operation cost according to fuel consumption rate and power/staff, etc.

Annual approximately $500-$1000USD annually maintenance according model, use situation.

One individual can service 02 unit incinerators. The team should have fundamental electrician understanding to operate/inspect/maintaince incinerator/burner/blower according to operation consumer guider, and know risk of waste to safeguard worker self with mandatory security element.

Q: The Residency time in secondary combustion chamber

A: 02 sec.

| Items/Model | TS10(PLC) | TS20(PLC) | TS30(PLC) | TS50(PLC) | TS100(PLC) |

| Burn Rate | 10 kg/hour | 20 kg/hour | 30 kg/hour | 50 kg/hour | 100 kg/hour |

| Feed Capacity | 20kg | 40kg | 60kg | 100kg | 200 kg |

| Control Mode | PLC | PLC | PLC | PLC | PLC |

| Combustion Chamber | 100L | 210L | 330L | 560L | 1200L |

| Internal Dimensions | 50x50x40cm | 65x65x50cm | 75x75x60cm | 100x80x70cm | 120x100x100cm |

| Secondary Chamber | 50L | 110L | 180L | 280L | 600L |

| Smoke Filter Chamber | Yes | Yes | Yes | Yes | Yes |

| Feed Mode | Manual | Manual | Manual | Manual | Manual |

| Voltage | 220V | 220V | 220V | 220V | 220V |

| Power | 0.5Kw | 0.5Kw | 0.5Kw | 0.7Kw | 0.7Kw |

| Oil Consumption (kg/hour) | 5.4–12.6 | 7.8–16.3 | 10.2–20 | 12.1–24 | 14–28 |

| Gas Consumption (m3/hour) | 6.2–11.4 | 8–15.7 | 9.8–20 | 9.9–26.1 | 10–32.2 |

| Temperature Monitor | Yes | Yes | Yes | Yes | Yes |

| Temperature Protection | Yes | Yes | Yes | Yes | Yes |

| Oil Tank | 100L | 100L | 100L | 100L | 200L |

| Feed Door | 30x30cm | 45x40cm | 55x50cm | 70x55cm | 80x60cm |

| Chimney | 3Meter | 3Meter | 5Meter | 5Meter | 10Meter |

| Chimney Type | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| 1st. Chamber Temperature | 800degree–1000degree | 800degree–1000degree | 800degree–1000degree | 800degree–1000degree | 800degree–1000degree |

| 2nd. Chamber Temperature | 800degree–1000degree | 800degree–1000degree | 800degree–1000degree | 800degree–1000degree | 800degree–1000degree |

| Residency Time | 2.0 Sec. | 2.0 Sec. | 2.0 Sec. | 2.0 Sec. | 2.0 Sec. |

| Gross Weight | 1500kg | 2200kg | 3000kg | 4500kg | 6000kg |

| External Dimensions | 140x90x120cm | 160x110x130cm | 175x120x140cm | 230x130x155cm | 260x150x180cm |

Incinerator (TS10 PLC)

Basic Info.

Additional Info.

Product Description

Nanjing Clover Medical Technology Co., Ltd. is a leading waste incinerator manufacturer in China.

Key Features: * All models with Dual combustion chamber. * Stainless Steel chimney/stack, long lifetime. *based on sequence * High temperature, long lifetime of incinerator. * Free or minimum installation on site. * High burn rate, from 10kgs to 500kgs per hourto 6ton per day. * PLC Control Plane. *based on order * New Design for pet animal cremation enterprise. * One year warranty on incinerator and components in stock.

| Items/Model | TS10(PLC) |

| Burn Rate | 10 kg/hour |

| Feed Capacity | 20kg |

| Control Mode | PLC |

| Combustion Chamber | 100L |

| Internal Dimensions | 50x50x40cm |

| Secondary Chamber | 50L |

| Smoke Filter Chamber | Yes |

| Feed Mode | Manual |

| Voltage | 220V |

| Power | 0.5Kw |

| Oil Consumption (kg/hour) | 5.4–12.6 |

| Gas Consumption (m3/hour) | 6.2–11.4 |

| Temperature Monitor | Yes |

| Temperature Protection | Yes |

| Oil Tank | 100L |

| Feed Door | 30x30cm |

| Chimney | 3Meter |

| Chimney Type | Stainless Steel |

| 1st. Chamber Temperature | 800degree–1000 degree |

| 2nd. Chamber Temperature | 1000degree-1200degree |

| Residency Time | 2.0 Sec. |

| Gross Weight | 1500kg |

| External Dimensions | 140x90x120cm |

Program Scope: 1. Hospital& clinic: Iatric Waste, Infectious Waste, Dressing, Bio-Waste, Medicine. 2. Slaughter House &Pet Hospital &Farm: Dead Animal, Bio-Waste. 3. Community & Sea Port & Station: Municipal Solid Waste, etc. 4.

Medical Waste Incinerator Trailer Installed

*Double combustion chambers*Smoke filter chamber and S.Steel chimney*Italy Riello Oil burner and PLC Auto. control*Heavy duty mobile trailer with safe parts*Minimal installation*Mobile by truck tractor1. Should be Trailer mounted Trailer Type2. Be able to burn Medical waste 100-200kgs per hour3. Diesel diesel oil type4. 220 V single phase5. Incinerating temperature range 800-1200 degree Celsius

/ * view gallery_shortcode() in wp-includes/media. php */.

.

smart.

.

.

{

(adsbygoogle = window.adsbygoogle || []).push({});|}

Text-align:.

Float: left.

Dimensions: 33%;.#gallery -1 img

#gallery -1. gallery-caption

Items/Model

TS100( PLC) ( Mobile Kind)

Photo

Principle

Medical Waste Incineration Treatment

Burn Price

Typical 100-200 kg/hour

Control Setting

PLC( Programmable Reasoning Controller Burner)

Burning Chamber

1200L

Internal Dimensions

120x100x100cm

Second Chamber

600L

Smoke Filter Chamber

Yes( Dry Scrubber)

Feed Setting

Guidebook

Voltage

220V

Power

0.9 Kw

Oil Utilization (kg/hour)

typical 20.4

Gas Consumption (m3/hour)

***

Infection Monitor

Digital Display

Temperature Level Protection

Yes

Oil Container

200L

Feed Door

80x60cm

Chimney

3Meter

Chimney Kind

Stainless Steel

1st. Chamber Temperature

800 ℃. gallery-item

/ * view gallery_shortcode() in wp-includes/media. php */.

Related

incinerator smoke filter

Posted on by africa-incinerator

All particles of the waste should achieve a high level of sterilization and not just “disinfection” due to the

continuous agitations

Description of the Treatment Cycle of the processor

- i) Loading

* The waste has to be loaded by dropping bagged and or boxed waste into the open loading door on the vessel.

* The loading door should be mounted at an angle on time top side, of the vessel with suitably sized to accommodate the

infectious wastes for which it is intended

* Over-loading or loading too tightly should not be an issue with this process, and hence no need of the special

operator skill.

- ii) Heat-up and fragmentation

* After loading, the vessel door is to be closed, and the outer jacket of the vessel is to be automatically filled with

high temperature steam, which should act as the main heating medium for heating the waste.

* During this heating cycle, the shall and mixing arms should rotate continuously, causing the waste to be fragmented

and continuously tumbled against the hot vessel walls.

* At this point, the waste is broken up into small fragments, and all material heats up rapidly, being evenly and

thoroughly exposed to the hot inner surfaces. The moisture content of the Waste will turn in to steam, and the vessel

will start to pressurize.

* Initially, no steam will be injected into the waste. If there is not enough moisture in the waste to pressurize

the vessel, a small amount of steam is to be automatically added until the desired pressure is reached.

* At the end of this period, the correct sterilization temperature and pressure should be reached, and the

sterilization period should start.

iii) Sterilization period

* The amount of steam fed to the outer jacket is to be regulated to maintain the desired temperature & pressure of the

inner vessel,

* The mixing arms (grinder) MUST continue to rotate throughout this cycle to ensure even sterilization pressure and

temperature for all wastes.

* The treatment time should be either15 minutes at 132° C OR 30 minutes at 121° C to achieve level 6log10

sterilization.

* The intense subjugation of the waste to high temperature and pressure moisture in a dynamic environment should also

cause the waste to hydrolyze that is a rapid decomposition of organic material.

- iv) De-pressurization:

* After the treatment time, the steam to the jacket should remain on, and the internal vessel is to be vented through a

condenser, and de-pressurized. Thus, the waste loses its water content through a combination of heat input from the

jacket and flashing of water due to depressurization.

- v) Dc-hydration

* Further dehydration is to be achieved by maintaining heat input and mixing – almost total dryness should be achieved.

- vi) Unloading

* Finally, steam to the jacket should shut off, the unloading door is to be opened

* Then the shaft and mixing arms are reversed to act as unloading mechanism and should scoop the waste fragments out of

the unloading door, onto a conveyor belt or directly into a waste container.

* The vessel should now be ready for another treatment cycle, having retained most of its heat for the treatment of the

next batch.