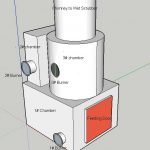

Doubel Combustion Chamber

All Incinerators are Doubel Combustion Chamber with One Fuel Burner Each. After Burner Technology for Completely Combustion and Cleaner World.

Read MoreHigh Temperature Incineration

Temperature Range 800 Degree to 1200 Degree in Combustion Chamber. Temperature Thermocouple Monitor and Controller. High Quality Fire Brick and Refactory Cement.

Read MoreGet Lastest News

There are latest incinerator news like technical, public news, business tender for medical waste incinerator,animal incineration, pet cremation

Read MoreNanjing Clover Medical Technology Co.,Ltd.

Email: sales@clover-incinerator.com | Tel: +86-25-8461 0201

Regular model incinerator for market with burning rate from 10kgs to 500kgs per hour and we always proposal customer send us their require details, like waste material, local site fuel and power supply, incinerator operation time, etc, so we can proposal right model or custom made with different structure or dimensions.

Incinerator Model YD-100 is a middle scale incineration machine for many different usage: for a middle hospital sickbed below 500 units, for all small or big size family pets (like Alaskan Malamute Dog), for community Municipal Solid Waste Incineration, etc. The primary combustion chamber volume is 1200Liters (1.2m3) and use diesel oil or natural gas fuel burner original from Italy.

Latest Post

General requirements of a 100 kg/hr 3 burning Chambers Burner

| General specifications of a 100 kg/hr incinerator | |||

| No. | Description | Parameter value | |

| model | HICLOVER YD100 | ||

| 1 | Machine working mode | Oil + Power | Oil + Power |

| 2 | Voltage | 220V C 3 phase or 1 phase | 220V 1P |

| 3 | Oil consumption (lit/hr) | Average 25-32 lit/hr/chamber | Average 33Liters/hour/total incinerator 3 burners |

| 6 | Incineration rate | 100 kg/hr = 400-600 kg/8hr | average 100kgs per hour |

| 7 | Feed mode | Manual | manual |

| 8 | Primary combustion rate | 1000 lit | 1080 liters |

| 9 | Secondary combustion rate | 240 lit | 207 Liters |

| 10 | Tertiary combustion rate | 416 lit | 452 liters |

| 11 | Combustion chamber material | High temp. resistant concrete | High temp. resistant concrete |

| 12 | Internal dimensions (1st chamber) | 100*100*100 cm (l*w*h) = 1000 lit | 120*100*90cm(l*w*h) = 1080 lit |

| 13 | Internal dimensions (2nd chamber) | 40*40*150 cm = 240 lit | Diameter 42*150cm=207 Liters |

| 14 | Internal dimensions (3rd chamber) | 40*40*260 cm = 416 lit | Diameter 60*160cm=452 Liters |

| 15 | External dimensions | 300*155*200 cm (l*w*h) | 220*160*370 cm (l*w*h) |

| 16 | Door opening | 90*90 cm | 90*90 cm |

| 17 | Additional air fan | 1 fan (on the door) | 1 fan (on the door) |

| 18 | Fuel type | Diesel oil/ | Diesel oil |

| 19 | Burner | Brand: Radiator or Hofmat | Italy Baltur |

| 20 | Chimney length | 3-4 meters | 5 Meters |

| 21 | Chimney type and material | H-type stainless steel, or High temp. resistant concrete | 1 Meter High temp. resistant concrete +4 Meter Stainless steel |

| 22 | Smoke and smell filter | Yes, two stages. | Dry Scrubber 2 stages |

| 23 | Temperature monitor | Yes, (for 1st and 3rd chambers) | Yes, (all 3 chambers) |

| 24 | Temperature control | Optional | yes |

| 25 | Oil tank | 500 lit needed. | yes |

| 26 | Burning efficiency | >98% | yes |

| 27 | 1st chamber temperature | 300-700 oC | 800-1000 oC |

| 28 | 2nd chamber temperature | 500-1000 oC | 1000-1200 oC |

| 29 | 3rd chamber temperature | 800-1200 oC | 1000-1300 oC |

| 30 | Smoke residency time | >2 sec. | >2 sec. |

| 31 | Gross weight | 5-8 tons | average 6.5 Ton |

| 32 | No. of Burners | 3 | 3 |

Tel: +86-25-8461 0201

Website: www.hiclover.com

Email: [email protected]

Email: [email protected]

2020-06-27

a commercial sized incinerator for cigarette along with cigarette waste

inciner8ter variation TS50 OR TS100 With delevery in Europe look Croatia.Please can you send me the deal for pet crematory equipment.details of Chemical waste incinerator.

For pet dogs to 90 kg. cremation devices for pets (Max. Size pet dog dogs till 80 kg )1. technical requirements is for burner just

2what is the capacity of burner in one hr?

3. 35 for burners, 8 for control circumstances, 1 for HD is that the weight of each product?

4. are these currently set up to ensure that the constructing ends up being simple in between control scenario and additionally burners with HD?oil heating system, 2sets (bigger capability).

Temperature level Thermocouple, 2 collections.

Oil Tank 100Liters, 1 set.

Thermal Gasket, 10 Meters.

Incinerator control Instance, 1 collection.

Blower, 1 set.a commercial sized incinerator for cigarette and tobacco waste. Info

Brand = Any Kind Of

Variation = Any Kind Of

400v/50hz

· Kind of waste – – – – timbers, tree branches, tree leaves, timber powder as well as card boards

· Daily Humans resources of operation = 7 hrs

· Daily produce waste ability = 10000kg.

THEE SETS OF BROCHURE ORIGINAL NEED TO BE RECIVED BY DHL + CD VEDIO.

THREE YEARS ENSURE TOTALLY FREE FREOM DELIVARY DAY As Well As FREE SPAR ELEMENT ALSO, GARANTEE LATTER SPAR PART NEED TO MEAN ONE DECADE FROM THE DATE OF DELIVEARY.

ELECTRIC SYSTEM DEMAND TO BE DELIVERD WITH SERVIC MANUAL IN ENGLISH EACH.

ELECTRIC REQUIRES TO BE 380-220 V HZ 60 FOR ALL TOOLS.

SUPPLY TIME ASB.

OFFER LEGITIMACY NEED TO BE 6 MONTHS.

IN SCENARIO OF ORDER I NEED.

2 COLLECTIONS OF CERTIFICATION OF ORGINE NEED TO BE STAMPED IT FROM SAUDIA CONSULAR OFFICE IN YOUR NATION.

COMMERCAL INVOICING( LEGALIZED FRO CHAMPER OF BUSINESS).

2 ORGINAL COSTS OF LADIN.

should BE SEND SOME ONE FOR FIXE In Addition To TRANING FOR 5 INDIVIDUAL IN EACH LOCATION.

REQUIRED TO BE SEND YOUR DIZIN FOR INSTALATION UNITS.

AWITING YOUR WONDERFUL REPLY

Medical Waste Incinerator for Coronavirus Disease

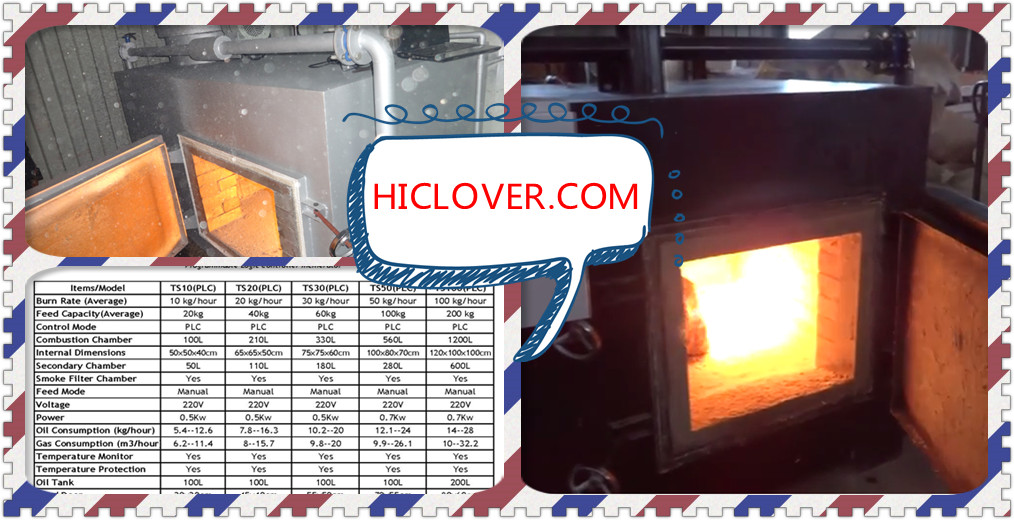

| Items/Model | TS10(PLC) | TS20(PLC) | TS30(PLC) | TS50(PLC) | TS100(PLC) |

| Burn Rate (Average) | 10 kg/hour | 20 kg/hour | 30 kg/hour | 50 kg/hour | 100 kg/hour |

| Feed Capacity(Average) | 20kg | 40kg | 60kg | 100kg | 200 kg |

| Control Mode | PLC | PLC | PLC | PLC | PLC |

| Combustion Chamber | 100L | 210L | 330L | 560L | 1200L |

| Internal Dimensions | 50x50x40cm | 65x65x50cm | 75x75x60cm | 100x80x70cm | 120x100x100cm |

| Secondary Chamber | 50L | 110L | 180L | 280L | 600L |

| Smoke Filter Chamber | Yes | Yes | Yes | Yes | Yes |

| Feed Mode | Manual | Manual | Manual | Manual | Manual |

| Voltage | 220V | 220V | 220V | 220V | 220V |

| Power | 0.5Kw | 0.5Kw | 0.5Kw | 0.7Kw | 0.7Kw |

| Oil Consumption (kg/hour) | 5.4–12.6 | 7.8–16.3 | 10.2–20 | 12.1–24 | 14–28 |

| Gas Consumption (m3/hour) | 6.2–11.4 | 8–15.7 | 9.8–20 | 9.9–26.1 | 10–32.2 |

| Temperature Monitor | Yes | Yes | Yes | Yes | Yes |

| Temperature Protection | Yes | Yes | Yes | Yes | Yes |

| Oil Tank | 100L | 100L | 100L | 100L | 200L |

| Feed Door | 30x30cm | 45x40cm | 55x50cm | 70x55cm | 80x60cm |

| Chimney | 3Meter | 3Meter | 5Meter | 5Meter | 10Meter |

| Chimney Type | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| 1st. Chamber Temperature | 800℃–1000℃ | 800℃–1000℃ | 800℃–1000℃ | 800℃–1000℃ | 800℃–1000℃ |

| 2nd. Chamber Temperature | 1000℃-1200℃ | 1000℃-1200℃ | 1000℃-1200℃ | 1000℃-1200℃ | 1000℃-1200℃ |

| Residency Time | 2.0 Sec. | 2.0 Sec. | 2.0 Sec. | 2.0 Sec. | 2.0 Sec. |

| Gross Weight | 1500kg | 2200kg | 3000kg | 4500kg | 6000kg |

| External Dimensions | 140x90x120cm | 160x110x130cm | 175x120x140cm | 230x130x155cm | 260x150x180cm |

| Items/Model | YD-30 | YD-50 | YD-100 | YD-150 |

| Burning Rate (kgs/Hour) | 30 kgs/Hr. | 50 kgs/Hr. | 100 kgs/Hr. | 150 kgs/Hr. |

| Feed Capacity (kgs) | 60 kgs | 150 kgs | 200 kgs | 300 kgs |

| Equipment Weight | 2300 kgs | 4000 kgs | 5300 kgs | 7000 kgs |

| Primary Chamber (Liters) | 360 | 900 | 1200 | 1500 |

| Secondary Chamber (Liters) | 200 | 200 | 500 | 500 |

| External Dimensions (cm) | 145x90x175 | 200x160x230 | 220x180x360 | 240x170x380 |

| Internal Dimensions (cm) | 100x60x60 | 120x90x85 | 130x100x90 | 150x100x96 |

| Oil Tank(Liters) | 200 | 300 | 300 | 300 |

| Door Opening (cm) | 48 x 60 | 62 x 80 | 55 x 80 | 59 x 81 |

| Chimney (M) | 5 | 5 | 10 | 10 |

| Chimney Type | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| Secondary Chamber | YES | YES | YES | YES |

| Mix-Combustion Chamber | YES | YES | YES | YES |

| Smoke Filter Chamber | YES | YES | YES | YES |

| Combustion Fuel | Oil/Gas | Oil/Gas | Oil/Gas | Oil/Gas |

| Residency Time | 2.0 Sec. | 2.0 Sec. | 2.0 Sec. | 2.0 Sec. |

| Temperature Monitoring | YES | YES | YES | YES |

| 1st. Chmaber Temperature | 800℃–1000℃ | 800℃–1000℃ | 800℃–1000℃ | 800℃–1000℃ |

| 2nd. Chmaber Temperature | 1000℃-1200℃ | 1000℃-1200℃ | 1000℃-1200℃ | 1000℃-1200℃ |

| Items/Model | YD-200 | YD-300 | YD-500 | YD-600 |

| Burning Rate (kgs/Hour) | 200 kgs/Hr. | 300 kgs/Hr. | 500 kgs/Hr. | 600 kgs/Hr. |

| Feed Capacity (kgs) | 400 kgs | 500 kgs | 800 kgs | 1100 kgs |

| Equipment Weight | 7600 kgs | 8300 kgs | 13000 kgs | 16500 kgs |

| Primary Chamber (Liters) | 2000 | 2400 | 4000 | 5500 |

| Secondary Chamber (Liters) | 500 | 1200 | 1500 | 1500 |

| External Dimensions (cm) | 270 x 185 x 380 | 260x220x420 | 320x220x460 | 360 x 220 x 475 |

| Internal Dimensions (cm) | 180 x 115 x 96 | 220x110x100 | 257x147x108 | 300 x 147 x 125 |

| Oil Tank(Liters) | 300 | 500 | 500 | 500 |

| Door Opening (cm) | 59 x 81 | 90 x 110 | 108 x 128 | 108 x 128 |

| Chimney (M) | 10 | 10 | 14 | 14 |

| Chimney Type | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| Secondary Chamber | YES | YES | YES | YES |

| Mix-Combustion Chamber | YES | YES | YES | YES |

| Smoke Filter Chamber | YES | YES | YES | YES |

| Combustion Fuel | Oil/Gas | Oil/Gas | Oil/Gas | Oil/Gas |

| Residency Time | 2.0 Sec. | 2.0 Sec. | 2.0 Sec. | 2.0 Sec. |

| Temperature Monitoring | YES | YES | YES | YES |

| 1st. Chmaber Temperature | 800℃–1000℃ | 800℃–1000℃ | 800℃–1000℃ | 800℃–1000℃ |

| 2nd. Chmaber Temperature | 1000℃-1200℃ | 1000℃-1200℃ | 1000℃-1200℃ | 1000℃-1200℃ |

| Items/Model | YD-10C | YD-20C | YD-30C | YD-50C |

| Burning Rate (kgs/Hour) | 10 kgs/Hr. | 20 kgs/Hr. | 30 kgs/Hr. | 50 kgs/Hr. |

| Feed Capacity (kgs) | 40 kgs | 40 kgs | 50 kgs | 80 kgs |

| Equipment Weight | 2100 kgs | 2100 kgs | 2300 kgs | 2500 kgs |

| Primary Chamber (Liters) | 200 | 200 | 250 | 400 |

| Secondary Chamber (Liters) | 140 | 140 | 140 | 140 |

| External Dimensions (cm) | 170x140x160 | 170x140x160 | 170x140x190 | 180x160x200 |

| Internal Dimensions (cm) | 55x55x65 | 55x55x65 | 55x55x85 | 70x70x85 |

| Oil Tank(Liters) | 50 | 100 | 100 | 150 |

| Door Opening (cm) | 38 x 48 | 38 x 48 | 38 x 48 | 45×55 |

| Chimney (M) | 5 | 5 | 5 | 5 |

| Chimney Type | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| Secondary Chamber | YES | YES | YES | YES |

| Mix-Combustion Chamber | YES | YES | YES | YES |

| Smoke Filter Chamber | YES | YES | YES | YES |

| Combustion Fuel | Oil/Gas | Oil/Gas | Oil/Gas | Oil/Gas |

| Residency Time | 2.0 Sec. | 2.0 Sec. | 2.0 Sec. | 2.0 Sec. |

| Temperature Monitoring | YES | YES | YES | YES |

| 1st. Chamber Temperature | 800℃–1000℃ | 800℃–1000℃ | 800℃–1000℃ | 800℃–1000℃ |

| 2nd. Chamber Temperature | 1000℃-1200℃ | 1000℃-1200℃ | 1000℃-1200℃ | 1000℃-1200℃ |

Tel: +86-25-8461 0201

Website: www.hiclover.com

Email: sales@hiclover.com

Email: hicloversales@gmail.com

2020-03-22

Clover Medical Incinerator

Product Description

5.

Required Specifications for Mobile Incinerator

Operational Capabilities

- PROCESS MINIMUM 1 TON PER DAY

- OPERATED WITH LIMITED TRAINING

- REGULAR MAINTENANCE CAN BE COMPLETED WITH LIMITED TRAINING

- COMPLIES WITH EURO / OR US-EPA EMISSION STANDARDS

- ABILITY TO BURN WASTE LUBRICANTS (POL)

- HANDLE ORGANIC SOLIDS (TO INCLUDE RMW)

- DEPLOYABLE

- MOBILE

- 24 HRS OF CONTINUOUS USE

- AUTOMATIC LOADING SYSTEM

- AUTOMATED ASH REMOVAL SYSTEM

- GAS SCRUBBING SYSTEM

- 95% REDUCTION OF SOLID WASTE

- OPERATE OFF DIESEL OR FUEL OIL

- CAPABLE OF BURNING 4 UNITS OF WASTE PER UNIT OF FUEL

- ABLE TO TAKE ALL COMBUSTIBLE WASTE TO INCLUDE: PAPER, PLASTIC, CARDBOARD, FOOD, USED OILS, SLUDGE, OILY RAGS, WOOD

- NO PRE-TREATMENT OF WASTE REQUIRED

- FIVE (5) YEAR COMPONENT WARRANTY

Technical Specifications

- OPERATION MANUAL AND TRAINING MANUAL FOR EACH INCINERATOR

- SET UP AND INSTALLATION INSTRUCTION MANUALS

- BLUE PRINT/ SCHEMATIC PROVIDED THAT OUTLINES THE PHYSICAL DIMENSIONS OF THE 20’ INCINERATORS

- INCINERATORS COMPOSED WITH HEAVY DUTY WELDED CONSTRUCTION

- OPERATED AND TRANSPORTED IN 20’ INCINERATORS (CONTAINERS)

- FULL FRONT AND OPTIONAL REAR ACCESS

- PRIMARY / SECONDARY TEMPERATURE CONTROLS