1. SCOPE OF FEATURE The work specified in the agreement will certainly consist of.

1. Supply, place as well as assign a heater as given in the technological specifications

2. Specification for adherence to OSHA along with other legal demand associating with Health and wellness of staff members throughout execution of the works covered in this tender.

3. Analysis and also prep work as well as building and building of a standard burner shed with one waste storage room (see the design)

4. Stipulation of treatment and also maintenance guidebooks as well as illustrations complete with upkeep schedule and guidelines.

5. Gas oil storage tank- Light steel1500 litres ability

6. Onsite training for operation in addition to maintenance team.

CRUCIAL

Tenderers that fail to conform with this need totally will have their tenders refuted. TECHNOLOGICAL NEEDS OF THE REQUIRED BURNER

2.1 General Recap

The plant have to have 4 unique areas that show 3 principles of turbulence, home time and likewise temperature level retention.

1. Overall plant layout

2. Feed chamber/charging

3. Key burning chamber

4. Particle scrubbers

5. Acid gas scrubbers.

6. The stack/chimney.

7. Minimum capability of crucial chamber = 0.18 cubic metres

8. Dropped price (price of waste incineration) = a the very least 20 kg per human resources

9. Need to have a full dimension counterbalance filling door enabling very simple access to the main chamber for filling as well as getting rid of ash.

Supply, Setup and also Appointing of A Burner in Eastern Hydros [Web Page 28

2.2 Feeding and additionally Billing

Controlled sanitary mechanical feeding that does not negatively influence the air temperature degree in the trick as well as likewise 2nd chambers of the heater shall be made use of.

2.3 Key Burning Chamber.

a) This chamber need to be outfitted with burners that make use of low sulphur gas.

b) The chamber should ensure a marginal leave temperature degree of 850 levels centigrade.

2.4 Secondary Burning Chamber (After burner)

a) Should be fitted with heating systems that utilize low sulphur gas.

b) Assurance 2nd air supply is controlled.

c) See to it residence time is not much less than two secs.

d) Guarantee that the gas temperature level as gauged versus the within wall in the extra chamber and also not in the fire location is not much less than 1100 levels centigrade.

e) Make sure the discharged oxygen web material of the sent out gases is not much less than 11%.

f) Assurance both primary as well as second burning temperature level levels are preserved up till all waste is totally ignited.

2.5 Particulate Removers

A mechanical fragment lover need to be incorporated after 2nd burning chamber for removal of particle toxic substances entrained in the flue gas stream. The particle collection agencies may include any of the abiding by or a mix thereof:.

a) Cyclone separator.

b) Electrostatic precipitators.

c) Fabric filters.

2.6 Chimney/Stack

l) The smokeshaft need to have a marginal altitude of 10 metres above ground degree in addition to clear the acme of the framework by not much less than 3 metres for all roofs. The topography along with elevation of nearby structures within 50 metres span must be thought about.

m) The smokeshaft should certainly show up to the motorist from the feeding area.

n) The minimal leave price require to be 10 metres per second in addition to at least twice the bordering wind speed (Efflux speed = wind speed x 2) whichever is higher to make sure no down cleaning of leaving gases.

o) The point for measurement of discharges will certainly be offered.

2.7 Instrumentation

a) Tool for finding out the within wall temperature as well as likewise not heater fire temperature level must be addressed both also second as well as key chambers.

b) A additionally noticeable and distinctive alarm system requirement to be mounted to signal the operator when the second chamber temperature degree drops to listed here the called for temperature.

c) A carbon monoxide gas as well as additionally oxygen meter/recorder should be provided

d) A smoke density meter/recorder require to be supplied.

e) A strong particulate meter/recorder should certainly be provided.

f) Any sort of various other tool that may be taken into account essential.

2.9 Exhaust Province

a) Burning efficiency (C.E) shall go to the very the very least 99.00% where C.E = %Co2 x 100/ [% CARBON DIOXIDE + carbon monoxide] b) The temperature degree of the main chamber will certainly be 800 +/- 50 degrees centigrade. c) The additional chamber gas house time shall most likely to the very least 1 second at 1050 +/- 50 levels centigrade with 3% oxygen in the pile gas.

d) Opacity of the smoke demand to not exceed 20% seen from 50 metres with naked eyes.

e) All the discharge to the air besides vapor or water vapour must be odor free and without mist, fume and also grains.

f) A 99.99% devastation and removal efficiency (DRE) for every single primary all-natural hazardous element (POHC) in the waste feed where DRE [( Success – – – – Wout)/ Win] x 100 where Success = mass feed price of the POHC in the waste stream fed to burner as well as Wout = mass exhaust price of POHC in the pile prior to the launch to the atmosphere.

g) The typical dioxin and likewise furan concentration in the exhaust should not exceed 80mg/m3 overall dioxins and furans if gauged for a duration of 6 to 16 hrs.

– – – – Guidebook technological monitoring is delivered with the devices with all descriptions of failings in addition to resolutions.

Capacity/island: 4000 kg/day; 25000 kg/day; 31000 kg/day; 48000 kg/day

Burning temperature– – over 12000C

Two chambers– – minimal

Wears down– – dioxin as well as additionally significant metaly– – much better after that Kyoto procedure

Discharge– – tracking system

Waste unloiding– – straight from waste track to incinerator

1. Is the residence time more than 2 seconds?

2. Is the primary and secondary air preheated?

3. Could it be provided as a continuous system?

4. Is there a monitoring system for operational parameter? (temperature)

5. Is there a data logging system?

6. Does it provide for control interventions to adjust waste feed, grate speed, and temperature, volume and distribution

of primary and secondary air?

7. Does it include auxiliary burners?

8. Does it include system that automatically stops waste feeding when combustion parameters are not appropriate?

9. Is it possible to have an automatic bottom ash unloading system?

1. Is the primary and secondary air preheated?

2. Could it be provided as a continuous system?

3. Is there a data logging system?

4. Does it provide for control interventions to adjust waste feed, grate speed, and temperature, volume and distribution

of primary and secondary air?

5. Does it include auxiliary burners?

6. Does it include system that automatically stops waste feeding when combustion parameters are not appropriate?

7. Is it possible to have an automatic bottom ash unloading system?

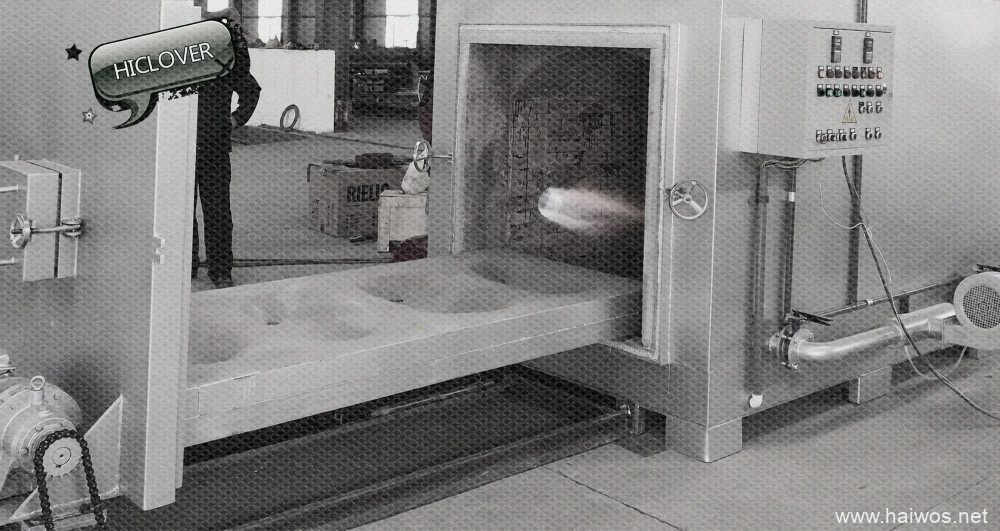

Incinerator

Rated Capacity: 100/KG/Hr

Type of Design: Double Chambered

Mode of Heating: Heating Elements

The Incinerator Plant is output wastes incineration from Different petrochemical units. In this project we want to incinerate all output wastes from petrochemical units and also produced high pressure steam from incinerator plant heat generated.

At first output waste from petrochemical collects and transfers to transit and sorting center in various forms. Input feeds of incinerator plant are shown in below table:

hospital incinerator manufacturers, Waste streams of petrochemical unit collect and store in Transit and Sorting Center.

In Transit and Sorting Center one laboratory must be considered.

In this center, waste will be classified in two groups:

– Unsuitable for burning

– Suitable for burning

Unsuitable waste for burning can be divided into the 4 categories:

– Buried materials

– Materials (wastes) that need to be stabilized before buried

– Materials (wastes) that can be sold.

– Wastes that can be returned to petrochemical.

Suitable wastes are classified into the two categories:

– Input wastes to rotary kiln, consist of solids and waste fluids.

– Input wastes to static kiln, consist of clean fluids and gasses.

All solid wastes must be transferred to storage pit from Transit and Sorting Center. Solid wastes storage pit is input of rotary kiln.

All fluid wastes must be stored and stabilized in Transit and Sorting Center. All storage and stabilization devices or facility must be considered. Storage and stabilization devices (facility) consist of:

Tanks, Pumps (Transfer, Loading & Unloading), Agitator (Mixer), Blanketing System, Flare system, Instrumentation and Control Systems, etc

Storage and stabilization capacity must be considered based on worst case (shut down).

Generally incinerator plant consists of two similar trains (capacity of each train is 100%). Each train consists of a rotary kiln and a static kiln.

| Items/Model | YD-10C | YD-20C | YD-30C | YD-50C |

| Burning Rate (kgs/Hour) | 10 kgs/Hr. | 20 kgs/Hr. | 30 kgs/Hr. | 50 kgs/Hr. |

| Feed Capacity (kgs) | 40 kgs | 40 kgs | 50 kgs | 80 kgs |

| Equipment Weight | 1200 kgs | 1200 kgs | 1800 kgs | 2200 kgs |

| Picture | ||||

| Primary Chamber (Liters) | 200 | 200 | 250 | 400 |

| Secondary Chamber (Liters) | 140 | 140 | 140 | 140 |

| External Dimensions (cm) | 170x140x160 | 170x140x160 | 170x140x190 | 180x160x200 |

| Internal Dimensions (cm) | 55x55x65 | 55x55x65 | 55x55x85 | 70x70x85 |

| Oil Tank(Liters) | 50 | 100 | 100 | 150 |

| Door Opening (cm) | 38 x 48 | 38 x 48 | 38 x 48 | 45×55 |

| Chimney (M) | 5 | 5 | 5 | 5 |

| Chimney Type | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| Secondary Chamber | YES | YES | YES | YES |

| Mix-Combustion Chamber | YES | YES | YES | YES |

| Smoke Filter Chamber | YES | YES | YES | YES |

| Combustion Fuel | Oil/Gas | Oil/Gas | Oil/Gas | Oil/Gas |

| Residency Time | 2.0 Sec. | 2.0 Sec. | 2.0 Sec. | 2.0 Sec. |

| Temperature Monitoring | YES | YES | YES | YES |

Nanjing Clover Medical Technology Co., Ltd., Neighborhood in Nanjing city, China.

YDC incinerator is newest design for waste treatment, laboratory incinerator, big incinerator mill uk, big scale incinerator, big scale incinerator medical waste, low capacity incinerators, very low cost incinerator manufacturer, include medical waste, animal cremation and other solid waste. This equipment quality structural for types of site, such as hospital, environmental division, animal cremation agencies, etc.. CLOVER Incinerator supply updated versions with dual combustion chamber, mix combustion space and smoke filter room using refractory lines, and the combustion room temperature up to 1200 deg C.

| Items | Specification | |||

| YDC Model | YD-10C / YD-20C / YD-30C / YD-50C | |||

| Main Product List | Primary Combustion Chamber | |||

| Secondary Combustion Chamber | ||||

| Mix Combustion Chamber | ||||

| Smoke Filter Chamber | ||||

| Incinerator Common Control Case | ||||

| Stainless Steel Chimney | ||||

| Italy oil/gas burner: 02 units | ||||

| Oil Tank (if oil fuel) | ||||

|

|

Style for Pets Cremation Business |

Movable system & & Vehicle. |

|

|

Independent Placement for Little Pet |

Model

A1500

Image

Burning Rate

Average 150 kgs/hour

Feed Capacity

Standard 350 kgs/feeding

Primary Burning Chamber

1500 Liters

Secondary Burning Chamber

500 Litres

Mix Combustion Chamber

Yes

Smoke Filter Chamber

Yes

Feed Setting

Manual

Voltage

220V/380V

Gas Type

Diesel Oil/ All-natural Gas/LPG

Burner

Italy Original

Oil Consumption (Diesel Oil)

Average 53.0 kg/hour

Gas Intake (Gas)

Average 63.6 m3n/hour

Internal Dimensions

150 x 100 x 100cm (main chamber)

Exterior Measurements

240 x 170 x 380cm (without chimney)

Temperature Level Screen

Yes

Oil Container Ability( if oil gas)

300 Liters

Door Opening

59 x 81cm

Chimney Length

10.0 Meters

Smokeshaft Type

Stainless Steel

Devices Gross Weight

8000 kgs