All particles of the waste should achieve a high level of sterilization and not just “disinfection” due to the

continuous agitations

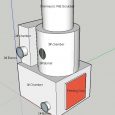

Description of the Treatment Cycle of the processor

- i) Loading

* The waste has to be loaded by dropping bagged and or boxed waste into the open loading door on the vessel.

* The loading door should be mounted at an angle on time top side, of the vessel with suitably sized to accommodate the

infectious wastes for which it is intended

* Over-loading or loading too tightly should not be an issue with this process, and hence no need of the special

operator skill.

- ii) Heat-up and fragmentation

* After loading, the vessel door is to be closed, and the outer jacket of the vessel is to be automatically filled with

high temperature steam, which should act as the main heating medium for heating the waste.

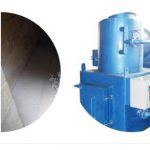

* During this heating cycle, the shall and mixing arms should rotate continuously, causing the waste to be fragmented

and continuously tumbled against the hot vessel walls.

* At this point, the waste is broken up into small fragments, and all material heats up rapidly, being evenly and

thoroughly exposed to the hot inner surfaces. The moisture content of the Waste will turn in to steam, and the vessel

will start to pressurize.

* Initially, no steam will be injected into the waste. If there is not enough moisture in the waste to pressurize

the vessel, a small amount of steam is to be automatically added until the desired pressure is reached.

* At the end of this period, the correct sterilization temperature and pressure should be reached, and the

sterilization period should start.

iii) Sterilization period

* The amount of steam fed to the outer jacket is to be regulated to maintain the desired temperature & pressure of the

inner vessel,

* The mixing arms (grinder) MUST continue to rotate throughout this cycle to ensure even sterilization pressure and

temperature for all wastes.

* The treatment time should be either15 minutes at 132° C OR 30 minutes at 121° C to achieve level 6log10

sterilization.

* The intense subjugation of the waste to high temperature and pressure moisture in a dynamic environment should also

cause the waste to hydrolyze that is a rapid decomposition of organic material.

- iv) De-pressurization:

* After the treatment time, the steam to the jacket should remain on, and the internal vessel is to be vented through a

condenser, and de-pressurized. Thus, the waste loses its water content through a combination of heat input from the

jacket and flashing of water due to depressurization.

- v) Dc-hydration

* Further dehydration is to be achieved by maintaining heat input and mixing – almost total dryness should be achieved.

- vi) Unloading

* Finally, steam to the jacket should shut off, the unloading door is to be opened

* Then the shaft and mixing arms are reversed to act as unloading mechanism and should scoop the waste fragments out of

the unloading door, onto a conveyor belt or directly into a waste container.

* The vessel should now be ready for another treatment cycle, having retained most of its heat for the treatment of the

next batch.

.

.  .

.  .

.