1. Is the residence time more than 2 seconds?

2. Is the primary and secondary air preheated?

3. Could it be provided as a continuous system?

4. Is there a monitoring system for operational parameter? (temperature)

5. Is there a data logging system?

6. Does it provide for control interventions to adjust waste feed, grate speed, and temperature, volume and distribution

of primary and secondary air?

7. Does it include auxiliary burners?

8. Does it include system that automatically stops waste feeding when combustion parameters are not appropriate?

9. Is it possible to have an automatic bottom ash unloading system?

1. Is the primary and secondary air preheated?

2. Could it be provided as a continuous system?

3. Is there a data logging system?

4. Does it provide for control interventions to adjust waste feed, grate speed, and temperature, volume and distribution

of primary and secondary air?

5. Does it include auxiliary burners?

6. Does it include system that automatically stops waste feeding when combustion parameters are not appropriate?

7. Is it possible to have an automatic bottom ash unloading system?

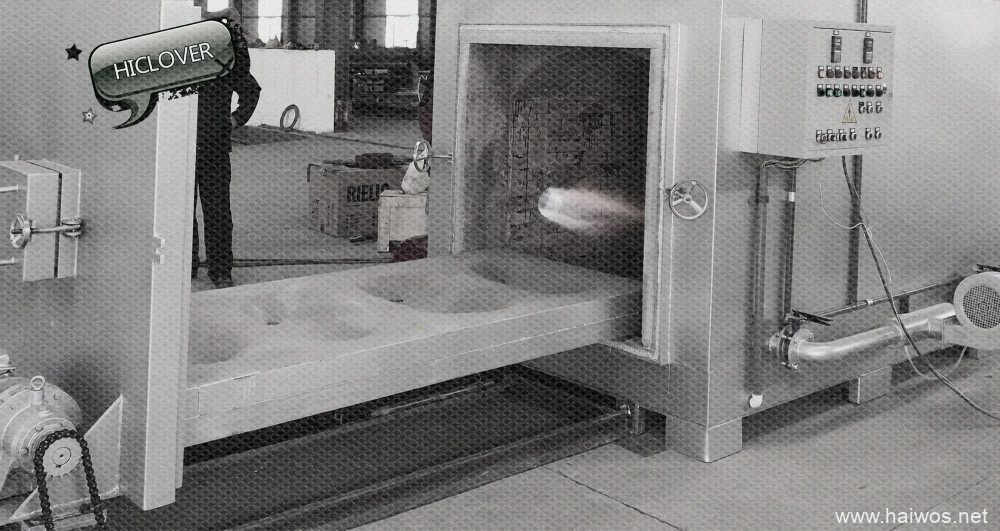

Incinerator

Rated Capacity: 100/KG/Hr

Type of Design: Double Chambered

Mode of Heating: Heating Elements