Author Archives: africa-incinerator

Incinerator Burner

Basic Info.

Additional Info.

Product Description

Please fill in following things and send back to us. Benefit of diesel hospital incinerator, algeria incinerators, animail incenrator, animal by-products of the incineration plant scheme, animal carcas incineration, We will study following important information and suggestion our product models, specification and so on.

| Item | Customer Request | Example |

| Application Scope | |

Hospital, Pet Crematory, Slaughter House, Laboratories, School, Community, etc. if for animal/pet, indicate animal size like: cat, dog, cattle, etc |

| What kind of waste? | ____, _____% ____, _____% ____, _____% |

Medical waste, dead animal, Municipal Waste, etc(detail name) or nature percent if for animal/pet, indicate animal size like: cat, dog, cattle, etc |

| Quantity Request | 01.02.03^..unit |

|

| Budget | $US Dollar. |

|

| Operating Time | The staff work Hours per day. Our incinerator can work up to around 18 hours per day. |

|

| Realization Date of project | In ___ year | |

| Waste Output Capacity per Day? | |

1000kgs Per Day^ |

| Request waste burn rate | Capacity: 100kgs Per hour^ | |

| Request waste feed capacity | Capacity: 100kgs per feed^ | |

| Whether Natural Gas Supply Local? | Yes or No. | |

| Local Power | If 380V and 220V valid? | |

| Product Installation Destination | |

Country or City name |

| DestinationSeaport name? | To check sea freight charge. |

|

| Customer | End-Customer, Agent, Government. |

|

| Method of contract | Tender or Negotiation | |

| Date of Tender limit | ||

| How did you know our company? | ||

| Other request or information | |

china lab waste incinerators

.Necessary tooling and gauges shall have also to be supplied.

14.Supplier shall have to arrange free training for user staff in operation and maintenance

15.Supplier shall have to provide related drawings/diagrams (civil, mechanical and electrical etc.)electrical load and

electrical circuitry

16.Warranty period shall be 24 months from date of proving test.

We are in the process of building a new hospital waste treatment plant and we are evaluating different technologies

from around the world. We are looking to incinerate approx. 1 to 2 tons of bio-medical waste per day using LPG for

heating. Please send me all general information and quotes for machines of all ranges that could meet our needs.

Also, please include emissions reports of all of the various machines that could be of interest to us especially with

regards to dioxins and furals as well as lists of recommendations from past clients.

medical hospital incinerator

Capacity: 30 Kg.

destruction capacity: 3.000 kcal/kg diesel.

max consume: 2.5 gal per hour.

1 camera:

1 burner capacity: 80.00 kcal

Type: K (Ni-CrNi)

enter size: 500x500mm

ash door: 190 x 250mm

all kind of medical, hospital, veterinary and industrial wastes by Incineration Process.

So, we’re interested with your Incinerator plants, and we’d like to get quotation and key features description of

different capacities of your Incinerator plants, concerning: small models (5 – 25 kg/hr); medium models (25-50 kg/hr)

and big models (50-100 kg/hr) and plus.

2 camera:

1 burner capacity: 80.000 kcal.

Air conbustion: 0.5 HP

Type: K (Ni-CrNi)

- Total waste produced per day: 10-12 tonnes;

- Hours of Operation: 10 hours a day;

- Fuel requirement: Diesel or waste oil preferred but LP gas will be considered;

Pet Animal Crematory Equipment

Clover Incinerator update A model incinerator for pet cremation and animal incineration. New design accept independent movable platform in-out incinerator combustion chamber. This new design is valid for model A900 and bigger model.

Email: cloverincinerator@gmail.com

Medical Waste Incinerators

Basic Info.

Product Description

Key Attributes: * All models with Dual combustion chamber. * Stainless Steel chimney/stack, long lifetime. *based on order * High temperature, long lifetime of incinerator. * Free or minimal installation onsite. * High speed, from 10kgs to 500kgs per hour, up to 6ton daily. * PLC Control Plane. *based on order * New Design for pet animal cremation business. * One year guarantee on incinerator and components in stock.

Application Scope: 1. Hospital& practice: Iatric Waste, Infectious Waste, Dressing, Bio-Waste, Medicine. 2. Slaughter House &Pet Hospital &Farm: Dead Animal, Bio-Waste. 3. Laboratories, Remote Locations, Disaster Relief Operations, Animal Cremation

Nanjing Clover Medical Technology Co., Ltd.. Is a leading waste incinerator manufacturer in China. We’re local producer and among the largest exporter of China. Pyrolytic incinerator gear technical is primary waste treatment each one the planet, such as Medical Waste, Animal Incineration, combustion chambers incinerator, company sale equipments of medical waste, concrete combustion chamber, concrete incinerator, containerized incinerator, Pet cremation and other good wste. The capacity from 10kgs/Hr. To 500kgs/Hr. Up to 6ton daily. Presentlywe supply different series for local client requirements and design upgraded incinerator with our leading technology. The upgraded design characteristic of our range of incinerators create them among the most cost effective in the world.

| Items | Specification | |||

| YD Model | YD-30 / YD-50 / YD-100 / YD-150 / YD-200 / YD-300 / YD-500 / YD-600 | |||

| Main Product List | Primary Combustion Chamber | |||

| Secondary Combustion Chamber | ||||

| Mix Combustion Chamber | ||||

| Smoke Filter Chamber | ||||

| Incinerator Common Control Case | ||||

| Stainless Steel Chimney | ||||

| Italy oil/gas burner: 02 units | ||||

| Oil Tank (if oil fuel) | ||||

INCINERATOR DIESEL DRIVEN

BURNER, DIESEL DRIVEN

waste kind: MEDICAL CARE WASTE

Waste calorific well worth: 4000KCAL/KG

Dampness Content: 10-25%.

Small Capacity: 50Kg/Hour set tons.

2nd Chamber: 2 Secs @ 850degrees C.

The major burning chamber have to ensure very little leave temperature degree is not less than 850 levels C.

INSULATION.

Calcium Silicate.

Limiting Regular solution limit 1000 levels C.

Thickness 25mm

THROUGHPUT.

50kg/hour at a small calorific well worth of 4,000 kcal/kg and additionally a regular mass thickness of 120kg/MCubed for standard waste and 160kg/MCubed for healthcare waste.

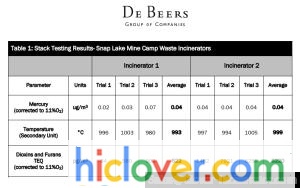

Mine Spews Toxic Fumes: NWT Air Regulations Not in Position

The elevated levels of dioxins and furans — published when plastic is burned or garbage is not fully incinerated — were captured during a four-day”stack test.” According to the World Health Organization,”dioxins are toxic and can cause reproductive and developmental problems, damage the immune system, interfere with hormones and also cause cancer.” The company contracted to do the testing in Snap Lake found that among the mine’s incinerators was emitting 6.5 times the acceptable limit, although another incinerator was emitting a whopping 65 times the acceptable limit (5,220 picograms per cubic metre on average, as

It is uncertain how long it was going on for, though the report noted the problem was clearly observable:”Black opaque smoke was noted for all tests early in the incineration cycle”

De Beers did not respond to EDGE’s petition for a meeting from the time of publication. But, as per a letter from De Beers’ Environment and Permitting Superintendent, Alexandra Hood, delivered to the GNWT and Environment Canada in January, the root cause of the issue was”not after standardized work practices,” and running the incinerators, which were just installed in 2013, at too low a temperature.

Since flunking the evaluation, De Beers has retrained personnel, rewritten operating procedures and introduced in new policy to shut down the incinerators if they are not fulfilling the right temperatures (if it’s safe to do so), based on Hood’s letter. A review of the Breeze Lake incinerators with a GNWT Lands Officer at March indicates De Beers has ameliorated the issue, at least in part:”No issues were noted during this inspection,” it states, and”the west incinerator which was burning waste in the time of inspection was emitting apparent exhaust gas without a black smoke coming out of the pile.”

Whether or not sufficient steps have been accepted, however, won’t be understood for decades: another stack test is not scheduled before 2019, according to a source close to the problem wishing to remain anonymous.

No GNWT regulation

The fact that, for an undetermined time period around July 2014, the Breeze Lake incinerators were pumping out unacceptable levels of toxic emissions is troublesome in itself. But it points to a far larger problem in the land; the GNWT doesn’t regulate emissions, require organizations to meet the CWS, or mandate pile testing. (The Mackenzie Valley Land and Water Board, likewise, doesn’t regulate air emissions.)

At a few points in her letter, Hood notes the lack of regulation, claiming De Beers”will conform with any regulatory requirements regarding incinerator stack testing once enabling legislation is approved and developed at the NWT.”

Without legislation in place, there’s nothing to force De Beers or other groups using incinerators (i.e. each mine in the territory), to keep their emissions in a secure level or undertake pile testing on a regular basis. Each mine has an Air Quality and Emissions Management Plan as a part of its environmental arrangement, but these programs simply dictate coverage requirements, not actual emission targets. And while Hood asserts”temptation, as measured against the Canada Wide Standards, will be managed through adaptive management and continuous improvement by De Beers,” there’s little government oversight of the”continuous improvement” without any penalties or other mechanisms to force polluting businesses to cure their manners.

This problem has been happening for ages. According to a Canadian Press report by 2011, the scientific journal Integrated Environmental Assessment and Management found sediments at a lake close to the Ekati Mine that had levels of dioxins and furans 10 times greater than those collected from an uncontaminated lake. The same report mentioned a 2007 study commissioned by Environment Canada which suggested”extensive, uncontrolled burning of wastes could lead to substantial accumulations of dioxins and furans in the local ecosystem, a few of which will persist for a few 81/2 years in levels approaching those believed to be of toxicological concern”

“In most cases we are under the level that health bureaus would (see ) for…” the study continues,”but we are getting there. And if you have more incinerators and more burning, you may well exceed those levels.”

The GNWT’s Department of Environment and Natural resources did not reunite EDGE’s request for comment on the lack of regulation.

Why no regulation?

The document states:”Parties need to take steps to reduce total releases from anthropogenic sources of dioxins, furans… together with the goal of their continuing minimization and where feasible (technically and socio-economically), ultimate elimination.” However, it adds,”each jurisdiction will determine the precise means of ensuring compliance” — essentially defanging the document by allowing states and lands renege on their commitment with no repercussions.

Other jurisdictions have taken proactive measures, bringing in legislation to regulate emissions in keeping with the CWS. The GNWT has not. They did bring in guidelines for handling biomedical waste in 2005, but they have been unwilling to regulate incinerators at mine websites. Their motive? The”waste incinerators operating at remote industrial sites within the NWT… are located on national crown land and are not governed by the Government of the Northwest Territories,” states a report by 2009.

This may have been accurate in 2009, however post-devolution it’s no longer true. Since April of this past year, the mines are on property controlled by the GNWT, yet there have been no moves out of legislators to begin regulating toxic emissions from other industrial incinerators. The last time the issue was discussed at the legislative assembly in 2011, Weledeh MLA Bob Bromley explained a”loophole in ecological rules is allowing an increasing amount of unregulated waste incinerators to discharge exceptionally toxic chemicals into the land and water.” He suggested,”if we take on new powers, we must be ready to move with law.”

Devolution has arrived, and incinerators are still operating in an unregulated environment. Considering all the talk of fracking and opening new mining jobs in the land, it’s now time, even more than ever, for the GNWT to receive its act together.

from: https://edgeyk.com/article/mine-spews-toxic-fumes-nwt-air-regulations-not-in-place/

from: https://edgeyk.com/article/mine-spews-toxic-fumes-nwt-air-regulations-not-in-place/

Medical Waste Incinerator HICLOVER TS10 PLC 10kgs per hr

|

Items/Model |

TS10( PLC) |

|

Photo |

|

|

Melt Rate |

Typical 10 kg/hour |

|

Feed Ability |

Standard 20kg/feeding |

|

Control Mode |

Programmable Logic Controller( PLC) Panel |

|

Combustion Chamber |

100L |

|

Interior Dimensions |

50x50x40cm |

|

Second Chamber |

50L |

|

Smoke Filter Chamber |

Yes |

|

Feed Mode |

Handbook |

|

Voltage |

220V |

|

Power |

0.5 Kw |

|

Oil Consumption (kg/hour) |

average 8.4 kg/hour |

|

Gas Usage (m3/hour) |

standard 10.1 m3/hour |

|

Temperature level Screen |

Yes |

|

Temperature Defense |

Yes |

|

Oil Storage Tank |

100L |

|

Feed Door |

30x30cm |

|

Smokeshaft |

5 Meter |

|

Smokeshaft Kind |

Stainless Steel |

|

1st. Chamber Temperature |

800 ℃–– -1000 ℃ |

|

second. Chamber Temperature |

1000 ℃ -1200 ℃ |

|

Residency Time |

2.0 Sec. |

|

Gross Weight |

1500kg |

|

Exterior Measurements |

140x90x120cm |

Tel: +86-25-8461 0201

Website: www.hiclover.com

Email: [email protected]

Email: [email protected]

2020-06-30