An open meeting for the community and anyone concerned was convened last Wednesday 1st October at Clann na Gael Community Hall. The meeting was well attended and was chaired by the Combined Residents Against Incineration (CRAI). The meeting was attended by local politicians and some representatives from Clontarf and Fairview.

Frances Corr, chairperson of CRAI outlined to the meeting the 17 years of concern and resistance to this project and reminded the meeting that on many occasions councillors have opposed and voted against this project. Despite this the latest Dublin City Council Chief Executive has signed the contracts with all the other Dublin Local Authorities to give Covanta the go ahead to start building. Covanta has stated in their recent release that they are ready to start building within weeks.

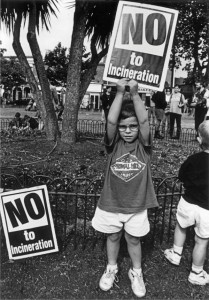

Many councillors wished to speak at the meeting. While being adamant about supporting resistance to the project, there were no specific solutions put forward by any councillors. Many locals advocated the need for civil resistance if necessary and many in the community are prepared to join with these type of actions.

CRAI are examining the specifics that were set down in the original planning conditions as there is a genuine concern that these may be breached, even at this early stage. The Poolbeg incinerator was originally planned on the basis of burning Dublin waste, yet given the size of the plant and the figures involved, it is highly likely it will need to take National waste to keep its need of 600,000 tonnes to accomplish it’s commercial goals and profits.

Although John Gormley was in attendance as a concerned resident, he was asked to speak to the meeting to give his views. Gormley outlined how the pursuit of “this incinerator was a stupid policy and would fossilize recycling efforts in Ireland.” With so much waste needed, it would twart national policy and motivation to recycle. Gormley emphasised that the project needed to be stopped “by getting into court as quickly as possible.”

A long time opposer to the project, Joe McCarthy, also spoke to the meeting and brought up many technical points regarding the incinerator. Joe McCarthy and Valerie Jennings are helping CRAI work out the technical points that may be contravening the conditions set out in the planning permissions for this plant and it is expected that there will be a legal challenge, such as a Judicial Review, initiated against this incinerator very soon.

In the meantime, there will be a growing resistance to the project on the ground. Northside groups were also in attendance. This included the Clontarf Residents Association as well as the Stop the Poolbeg Incinerator Campaign, a concerned group based in Marino and Fairview that have formulated since the announcement that this industrial practice will now take place in the heart of Dublin Bay. There seems to be much concern and alarm by many Dublin residents who may have been taken by surprise that this incinerator is being built when so many were of the view that it had been terminated some time ago.

CRAI announced a march to the Dail on Wednesday 22nd October starting at 5pm in Ringsend. “It’s our first march on the Dail and it’s happening there as we believe that is where the power lies,” says Frances Corr. The march will convene in Ringsend at the church and set off for the Dail. It is hoped that this march will draw in all those who have genuine concerns from Dublin and beyond. Anyone who cannot make the walk can join at the Dail by 6pm.